Thin-film thermoforming

Thermoforming definition :

This process consists to transform thermoplastic materials such as films, sheet and plates to 3D object. Thermoplastic materials take a rubbery consistency in high temperature.

At this time, the plastic is easily form by a tooling and frozen in this form by cooling.

Choosing your thermoforming method depends on :

- Deformation to be imposed

- The shape of manufacturing object

- Type of thermoforming material

- Material thickness

- Economics means : machines, molds, number of series …

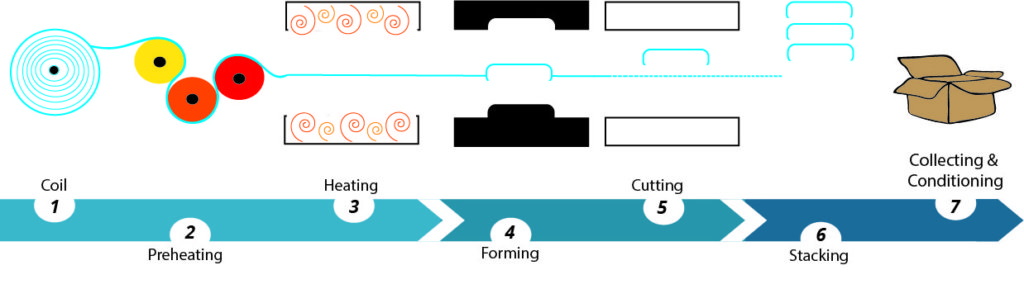

Thin-film thermoforming :

We using the term thin thickness when the plastic is a bobine. The thin-film thermoforming consists in taking this plastic coil, heating it to soften it, applying it to a mold to convert the plastic by suction.

Thin-film thermoforming advantages :

- Cadences more important

- Shorter heating time

- Various applications

- Reactivity

Type of product :

- Shell

- Trays

- Pots

- Blisters

- Shipping trays

- Casting mold

- Boxes

- Coffrets

Benefits of plastic material in packaging :

- Lightness: their density is between 0.92 and 1.39 and can go down to 0.01 for expanded materials.

- Mechanical resistance: variable according to the polymers, it can reach high values as for polycarbonate.

- Transparency: many plastics are transparent or translucent

- Inalterability: plastics are resistant to external aggressions (humidity, microorganism …)

- Aesthetics: the infinite variety of shape, their beautiful appearance and their colors make it possible to make packaging of the most attractive.

- Waterproofing: Even under a thin layer, plastics are a serious obstacle to moisture and gases. The use of so-called complex composite materials reinforces this function.

- Natural asepsis: during processing, plastic materials are heated to temperatures between 110 ° C and 190 ° C. This temperature brings asepsis to the packaging they constitute.