Thick thermoforming

Thermoforming definition :

This process consists to transform thermoplastic materials such as films, sheet and plates to 3D object. Thermoplastic materials take a rubbery consistency in high temperature.

At this time, the plastic is easily form by a tooling and frozen in this form by cooling.

Choosing your thermoforming method depends on :

- Deformation to be imposed

- The shape of manufacturing object

- Type of thermoforming material

- Material thickness

- Economics means : machines, molds, number of series …

Thick thermoforming :

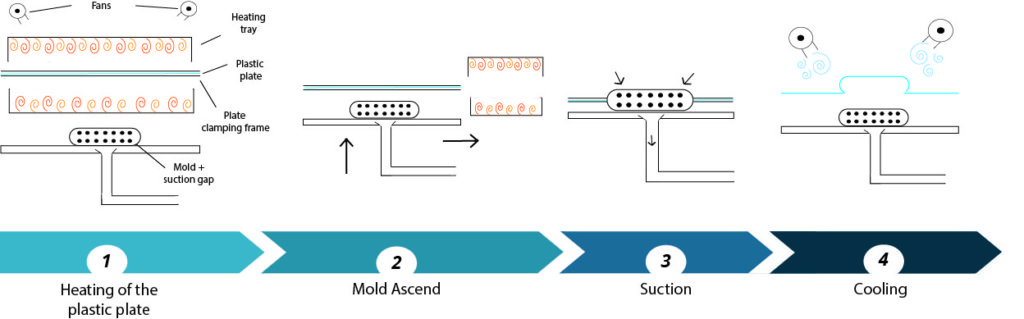

This kind of thermoformage consists by forming a plastic plate. This plate will be heated and then applied to a mold to convert the plastic by suction.

As a result of this thermoforming, the parts are milled and trimmed in order to obtain the final piece thanks to 5-axes machining centers.

Thick thermoforming advantages :

- Small, medium or large series

- Pieces with large size

- Reduce tooling cost

- Short R&D time

- Weight of pieces reduced compared to sheet metal

- Wide range of material able to answer at constraints (transparency, shock, fire, UV, chemical resistance …)

Type of product :

- Transport covers : quad bodywok, cover for bus mirror, calender truck …

- Equipment of goods covers

- Shipping trays, handling palette

- Equipment goods for medical or paramedical : hospital furniture, mattress …

- Professional display

Associated services :

- Assembling, machining, bending, ultrasonic welding

- Installation of accessories: fasteners, foam, wires, injected parts

- Finishing: silkscreening, painting, stickers, chrome plating

- Countertype of all types of colors

- Bonding of reinforcements

- Insert label holder

- Riveting of complementary elements

- Bonding labels

- Filter welding